Cobra ft. AST & Autoblog

As a Dutch company, we love to develop products together with companies within our country. When we saw the post from Autoblog, in which they indicated that they were looking for companies that could help modify the Suzuki Swift Sport long-termer together with them, we were one of the first to contact them to look at the possibilities with regard to the car's suspension. After all, we already had a set of lowering springs in our range. During the conversation we soon came to the conclusion that we had to go for a coilover kit to really give the car a different character.

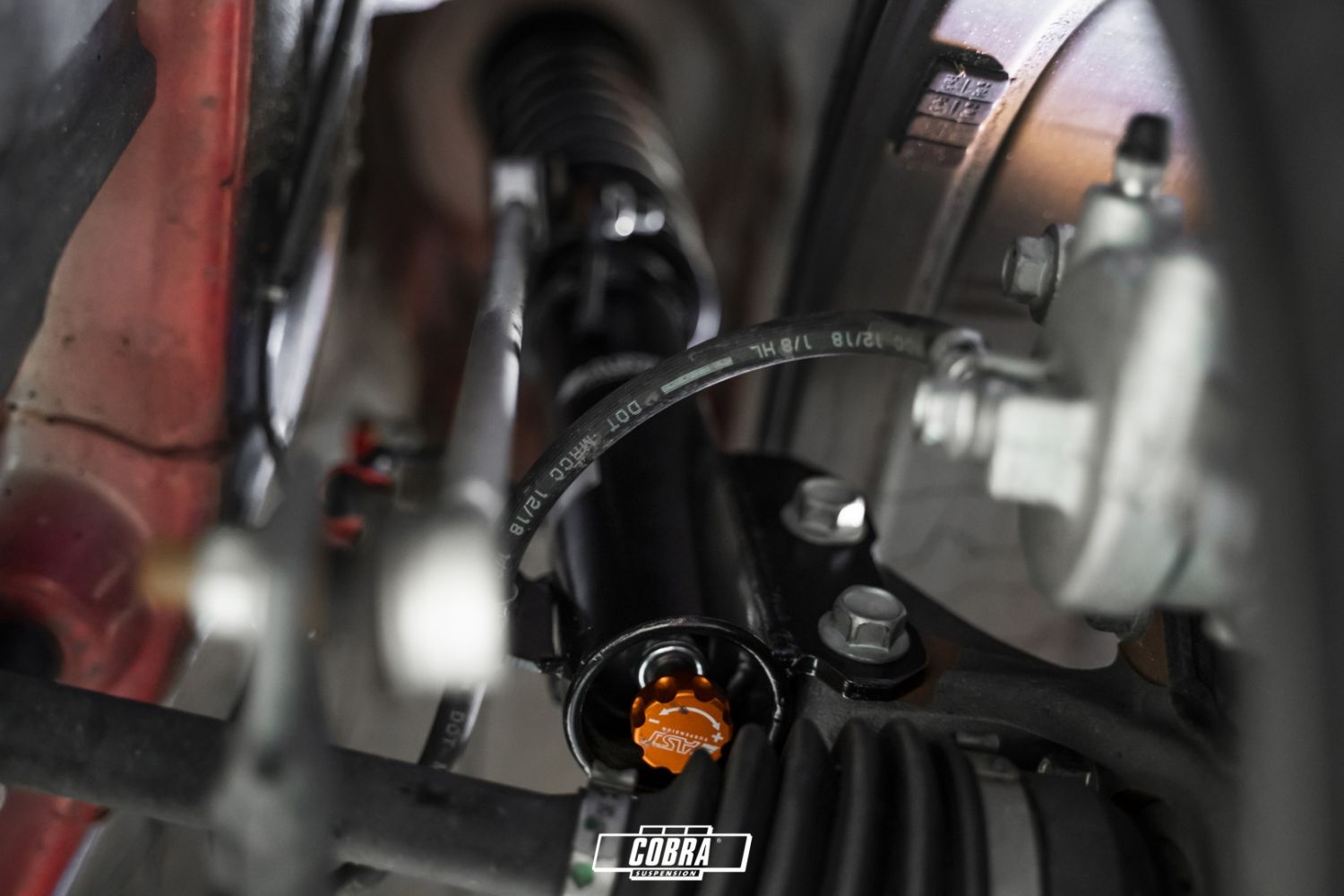

The development of a coilover kit

We wanted to combine the knowledge of producing springs with the knowledge of the production of dampers in order to achieve a perfect end product. For this we knocked on AST's door. Together with Autoblog and AST, we set ourselves to work. That started with measuring the original components. AST looked at the original parts and designed the shock absorbers in their 3D CAD systems based on this data. At Cobra Suspension we were responsible for the springs. Together with AST, we chose a certain setup, with which we were able to improve the Swift Sport of Autoblog and Suzuki Nederland considerably with regard to the suspension of the car.Cobra Suspension Springs

Meanwhile, we were responsible for producing a new rear spring. The rear setup of the car could be executed in two ways. With a true-coilover and a non-coilover. Both have the option to adjust the car up and down, but with a true coilover the spring is on the shock absorber. With a non-coilover the spring is in the control arm, where it is originally as well. We have developed a progressive spring which contributes to a better driving character, but also to the lowering. We have done this while maintaining the original fitment of the spring. Because this is a prototype, we produced not one, not two, but three sets of springs, each with a different character. We do this in every test, including the development of lowering springs, in order to give ourselves enough variation and reference material with which we can ultimately design a perfect end product.